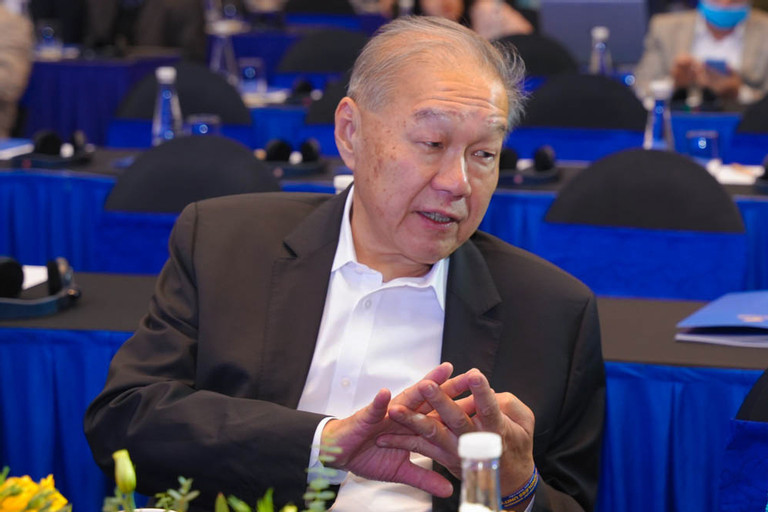

The professor is known for his decisive role in figuring out a roadmap for the Singaporean semiconductor industry. He talked with the press during his working visit to Vietnam recently about opportunities for the country.

What do you think about the semiconductor industry in Vietnam?

I have learned from mass media that Vietnam has been going very rapidly in its process of industrialization in general and semiconductor manufacturer attraction in particular.

Because of geographical matters, some multinationals plan to locate their production bases from another country to Vietnam. It would be great if Vietnam can grasp the opportunity.

Vietnam ranks second in the world in rare earth reserves. Can Vietnam take full advantage of this to develop the semiconductor industry?

The materials the semiconductor industry needs include basic ones. For example, for conventional semiconductor, its input material is silica, or sand, which is abundant and easy to find. There are also new materials such as silicon, carbide and gallium, which combine about 5-6 elements to form semiconductors. With traditional semiconductor, its input materials are not expensive.

Many new materials have been invented for semiconductor production. But the industry doesn’t always require expensive and difficult to be found materials such as rare earth. The potential of the natural resource is mostly prominent in developing magnetic materials, such as electric vehicle production.

Many experts believe that Vietnam should focus on chip designing, because the resources needed to build a semiconductor supply chain are enormous. What do you think about the idea?

Semiconductor industry is an ecosystem which comprises many parts, including ones which require huge investment, such as FAB, or chip manufacturing plant, about $4-5 billion. Perhaps Vietnam is not ready to invest in FAB, which should be undertaken by giants.

There are many parts in the industry, such as designing, assembling and testing, etc…In the case of Singapore, we did not invest in FAB. We invest in assembling, measuring and then step by step to designing.

When we had nothing, we attracted foreign companies to Singapore to start building an electronics industry. From there, we gradually developed our production capacity to join the value-added chain.

Now, we have all parts of the semiconductor electronics industry value chain, from assembly to designing companies, measurement and testing.

What do you think Vietnam should do to develop the semiconductor industry and attract foreign companies?

I think there are some experiences for Vietnam to consider. We apply policies to attract foreign investors, including a transparent legal framework, stable political conditions and tectonic government. We also encourage talented workers to emigrate to Singapore to work.

Trong Dat